DESIGN OF THE MAIN ENGINE FOUNDATION OF SHIP X TO SUPPORT MAIN ENGINE REPOWERING

DOI:

https://doi.org/10.30649/ijmea.v2i2.396Keywords:

design, foundation, main engine, load, repowering, strain, strength, stressAbstract

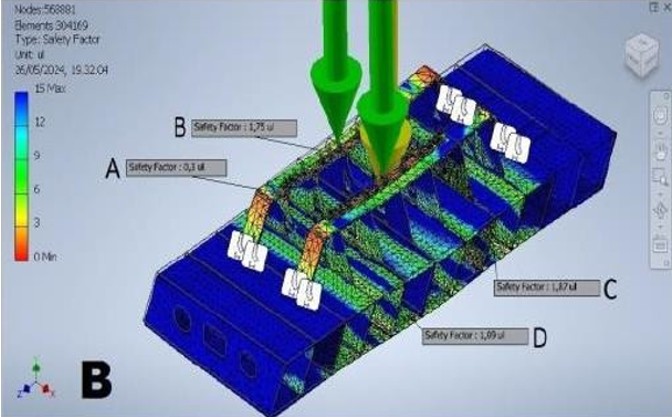

Ship “X” is one of the motor ships built in 1974 and is of the passenger type. Repowering is planned because the current speed is deemed insufficient to meet the expected operational targets. The ship uses the previous main engine with a capacity of 4 x 1340 HP to 2 x 2600 HP. An important part of the main engine is the foundation located at the bottom, because the foundation is attached to the main engine with a large power, the foundation must effectively ensure the safety of the hull structure to withstand a wide variety of forces that can be provided by loads on the foundation. The engine foundation must be able to withstand the load on it without causing shear stress, as if the engine has become an integral part of the ship itself. Given that this will be done, a new main engine foundation design process will be made. There are two types of materials simulated, namely bki grade A and B standard steel, with two loads during operation, namely a fixed load of 29,577.15 N and a total load of 165,128.41 N. In carrying out the research, modeling and simulation were carried out with Autodesk Inventor software. So, this research produces the most efficient material, namely bki grade A steel, because it has a greater yield strength and tensile strength. The material has simulation results with minimal and maximum difference values in %, Stress XY 0.56%, Stress Z 0, 11%, Stress YY 0.11%, Stress stress and strain of Von Mises Stress 0.05%, 1st Principal Stress 0.18%, 3rd Principal Stress 0.18%, Stress XX 0.03YZ 0.02%, Stress ZZ 0.07, Equivalent Strain 0.44%, 1st Principal Strain 0.46%, 3rd Principal Strain 12.25%, Strain XX 0.02%, Strain XY 0.18%, Strain XZ 0.09, Strain YY 0.22%, Strain YZ 0.36%, Strain ZZ 0.09%.

Downloads

References

S. A. Fitri, “Optimization of Propeller Selection Due to Engine Replacement for the Charma Rucitra 3 Ship,” ITS Repository, 2023. [Online]. Available: http://repository.its.ac.id/id/eprint/97017

L. Pekerjaan, “Technical Specifications,” pp. 1–10, 2014.

M. A. Asis, “Faculty of Engineering, Hasanuddin University Gowa 2020,” 2020. [Online]. Available: http://repository.unhas.ac.id/id/eprint/1828/

S. Federico and H. N. Wibowo, “Performance Study of Fast Boat Engines After Re-Powering,” ResearchGate, vol. 02, no. 05, p. 2017, 2012.

F. S. Perdana, A. Akbar, and H. Mahmudi, “Analysis of Material Strength and Frame of a 1.2-Ton Cattle Rolling Device Using Autodesk Inventor Software,” J. Semin. Nas. Inov. Teknol., pp. 1–7, 2022.

K. M. Y. Emily, N. A. Nugroho, and P. Herijono, “Info Articles Abstract,” vol. 2, no. 1, pp. 2021–2022, 2021. [Online]. Available: http://e-journal.ivet.ac.id/index.php/maristec

S. Jokosisworo and E. Widianto, “Analysis of Machine Foundation Strength on Mt. Nsl-Iv Due to Changes in Main Engine Capacity at Pt. Jasa Marina Indah Using the Finite Element Method,” Kapal, vol. 8, no. 2, pp. 79–81, 2012.

Biro Klasifikasi Indonesia, “Section 20 Fatigue Strength,” Rules Hull 2019 Edition, vol. II, pp. 20–7, 2019.

Yanmar, “Marine Diesel Engine Products Guide: Limitless Blue Skies and Oceans.”

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 International Journal of Marine Engineering and Applications

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.