RELIABILITY-BASED PREDICTABLE MAINTENANCE OF THE 2800 GT CONTAINER SHIP FUEL SYSTEM

DOI:

https://doi.org/10.30649/ijmea.v2i1.383Keywords:

Ship’s Fuel System, Reliability, Fault Tree Analysis, Failure Mode and Effect Analysis, Weibull DistributionAbstract

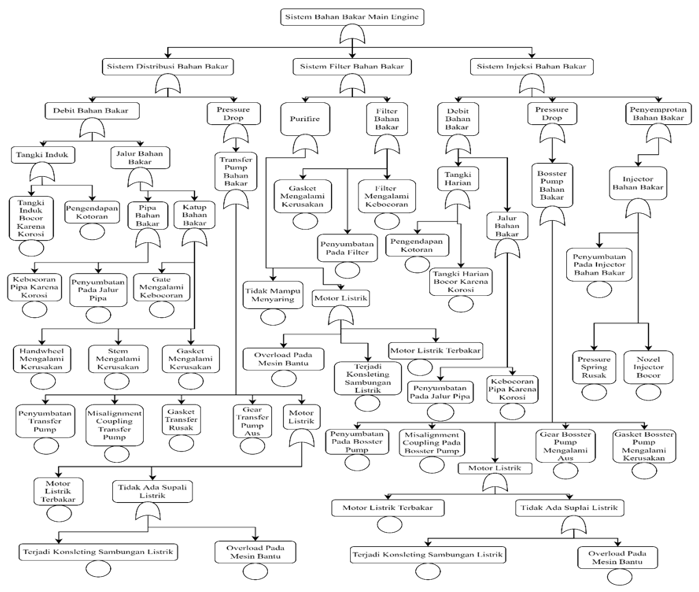

The fuel system is a supporting system for the ship's main engine because this system directly affects the performance of the main engine. The fuel system is so important that it will have a direct impact on the performance of the main engine and affect the ship's operations. To prevent danger or loss resulting from fuel system failure, a reliability-based maintenance analysis is needed. This research will analyze failures and create a maintenance schedule for the fuel system on the ship's main engine. In completing this research, a qualitative method was used, namely using Fault Tree Analysis (FTA) and Failure Mode and Effects Analysis (FMEA. Then, quantitative analysis was carried out using the Weibull distribution to determine the mean time to failure (MTTF). The results of the research showed that the predicted maintenance of the main engine fuel system was correct based on the reliability value calculation. The reliability value of the Transfer Pump component was 5950 hours with a reliability of 0.66, the Booster Pump 4325 hours with a reliability of 0.749, the Purifier 5530 hours with a reliability of 0.66, the Injector 2010 hours with 0.93 reliability, Filter 967 hours with 0.86 reliability.

Downloads

References

Sofi’i, M., & Djaja, I. K. (2008). Teknik Konstruksi Kapal Baja. In Departemen Pendidikan Nasional.

Awwalin, R., & Nugroho, S. (2019). Studi Penambahan Fungsi Kapal Melalui Pemanfaatan Kapal Tipe Lighter Aboard Ship (LASH) untuk Pulau-Pulau Kecil: Studi Kasus Kepulauan Kangean Kabupaten Sumenep. Wave: Jurnal Ilmiah Teknologi Maritim, 12(2), 61–72. https://doi.org/10.29122/jurnalwave.v12i2.2917.

Kececioglu, D. B. (2002). Reliability Engineering vol2. Destech Publications, Inc

Zaini, A. (2020). Analisa Faktor Kegagalan Produksi Part Kapal dengan Metode FMEA dan FTA. Universitas Hang Tuah Surabaya.

Dwisetiono, D., Marjono, M., Wike, W., Wahyudi, S., Karyatanti, I., Facility Layout Improvement in Shipyard Support Industries with Systematic Layout Planning to Increase Productivity, (2023) International Journal on Engineering Applications (IREA), 11 (4), pp. 249-258.

doi:https://doi.org/10.15866/irea.v11i4.23732

Rosadi, A. (2020). Analisa Resiko kegagalan Pompa Floating Dock II dengan FMEA di PT. Dok dan Perkapalan Surabaya. Universitas Hang Tuah Surabaya.

Otaya, L. G. (2016). Distribusi Probabilitas Weibull Dan Aplikasinya (Pada Persoalan Keandalan (Reliability) Dan Analisis Rawatan (Mantainability). Tadbir: Jurnal Manajemen Pendidikan Islam, 4(2), 44–66.

Dwisetiono, & Asmara, R. G. E. (2022). Analisa Kegagalan Sistem Bahan Bakar Kapal Dengan Menggunakan Metode Preliminary Hazard Analysis (PHA) dan Fault Tree Analysis (FTA). Jurnal Teknik Dan Sains Fakultas Teknologi Lingkungan Dan Mineral Universitas Teknologi Sumbawa, 3, 34–39.

Yaqin, R. I., Zamri, Z. Z., Siahaan, J. P., Priharanto, Y. E., Alirejo, M. S., & Umar, M. L. (2020). Pendekatan FMEA dalam Analisa Risiko Perawatan Sistem Bahan Bakar Mesin Induk: Studi Kasus di KM. Sidomulyo. Jurnal Rekayasa Sistem Industri, 9(3), 189–200.

Hazhiah, I. T., Sugito, & Rahmawati, R. (2012). ESTIMASI PARAMETER DISTRIBUSI WEIBULL DUA PARAMETER MENGGUNAKAN METODE BAYES. Media Statistika, 5, 27–35.

Risna, & Lutfi, M. (2019). Analisa Perawatan Berbasis Keandalan Pada Sistem Bahan Bakar Mesin Utama KMP. Bontoharu. JST (Jurnal Sains Terapan), 5(1). https://doi.org/10.32487/jst.v5i1.540.

Alwi, M. R. (2016). Reliability Centered Maintenance Dalam Perawatan F.O. Service Pump Sistem Bahan Bakar Kapal Ikan. Jurnal Riset Dan Teknologi Kelautan (JRTK), 14(1), 77–86.

Ponidi, P., & Salam, I. (2019). Fuel Analysis HSD Diesel and Bio Diesel Related Engine Performance Reach Staker Kalmar in PT. Meratusline. R.E.M (Rekayasa Energi Manufaktur) Jurnal, 4(1). https://doi.org/10.21070/r.e.m.v4i1.1537.

Sutanto, F. A. (2012). Implementasi Teknik Keandalan untuk Mengoptimalkan Interval Perawatan dan Jadwal Penggantian Komponen Kritis Mesin Panel Welding. Institut Teknologi Sepuluh Nopember.

https://doi.org/10.26593/jrsi.v9i3.4075.189-200

Billinton, R., & Allan, R. N. (1984). Reliability Evaluation of Power Systems. Second, Quality and Reliability Engineering International. In New York and England: Plenum Press. https://doi.org/10.1016/S0003-4975(10)62926-8

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 International Journal of Marine Engineering and Applications

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.